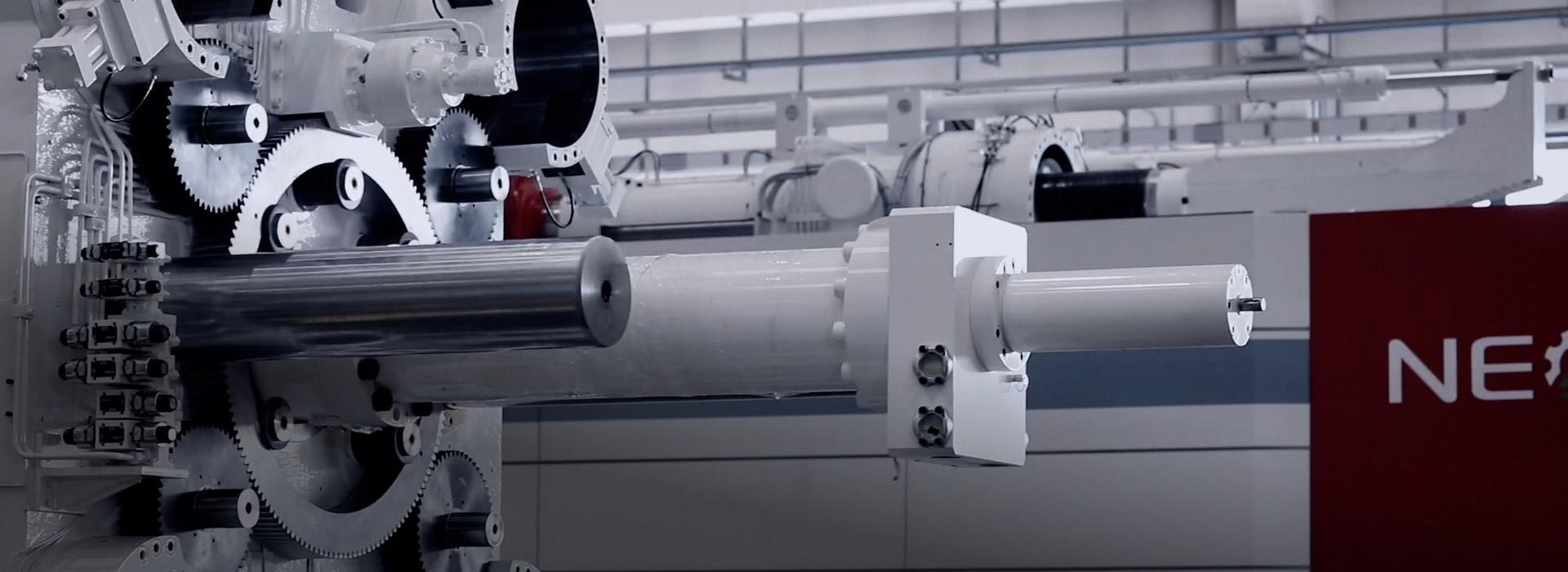

The premium Die Casting Machine from IDRA.

The superior choice.

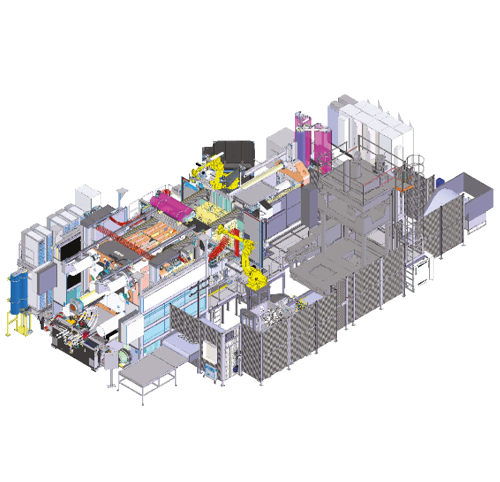

NEO is anticipating the future of OEM, offering the perfect solution for the production of aluminum parts for Hybrid – full electric vehicles (Structural, Battery box, Rotors) and Production of large aluminum parts made with full automated HPDC cells (Blocks, Auto gears, Multi-cavity structural).

NEO innovative technology offers best-in-class performance with excellent injection performance, a high dynamic force with strong intensification for final pressure and a complete setting flexibility with precise, and stable production parameters.

DOWNLOAD

FORECO, FOREVER

Idra Group is going all-in in Forward thinking Eco Complimentary Commitment. NEO is the first IDRA system fully designed for a sustainable foundry or “Efficient Manufacturing Facility” in order to meet these amazing accomplishments:

Low scrap waste from production.

High efficiency and optimized energy usage.

Sustainable factory environment taken into consideration at the design stage.

Helping to lower industrial production costs.

NEO also offers unparalleled guaranteed long life and reliability.

Low Energy cost

Energy efficient motors with speed control.

Minimized injection pressure loss and accumulator recharge time.

Fast cycle times

Integrated high flow hydraulic manifold blocks.

Increased pump capacity utilizing DCP technology.

User friendly controls

Inject Computer 3.2 (best in class machine management software).

Eliminated push button Unit using Multiple touch screens.

Cell controller Single point setting for integrated peripheral automation.

Easy maintenance and minimal risk of fluid loss

All-in-one hydraulic manifolds.

Limited use of external pipe-work.

Designed-for-access mechanical groups with new guard design.

Fit for complex parts manufacture

Closed loop 5S regenerative control of the injection velocity.

Programming and control of process parameters.

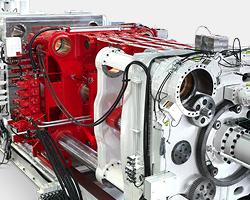

New Injection Series 5S©

- Closed loop regenerative injection with aux servo pump for efficient recharge.

- Extended velocity control valve life by balance of hydraulic forces.

- High dynamic force necessary to fill difficult castings.

- Maintaining same final pressure requirement for porosity in power train castings.

GUARDING SYSTEM

- Reducing complex electrical parts and stops.

- Simplified assembly of the system with modular scalable construction.

- Increased safety requirements for access while machine is running.

- Reduced emissions from the die casting process.

DCP HYDRAULIC SYSTEM

- Reduced energy consumption per cycle of the DCM cell.

- Separated closing and injection pump systems.

- Allowing subgroup testing for the injection system.

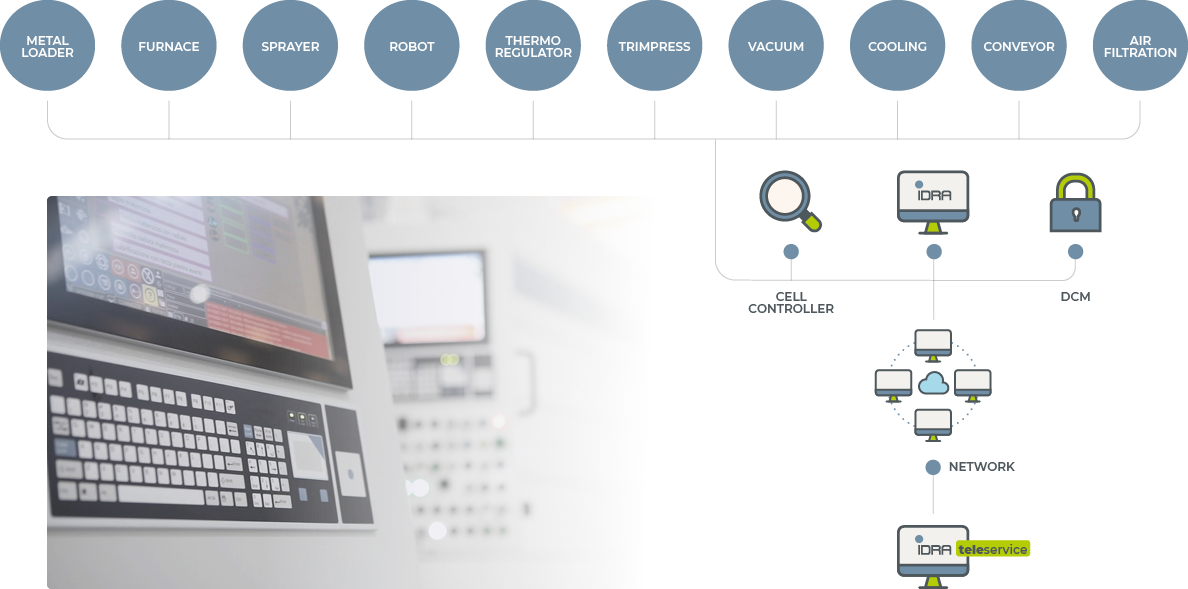

CELL CONTROLLER INTEGRATION

- A more efficient way of managing the software requirements for complicated cells.

- Standard DCM software avoids instability and unnecessary stops.

- Flexibility and customization for many different configurations.

- Easy integration with the best in market products.

NEO debuts the new revolutionary patented injection system, a result of an amazing R&D effort and two years of hot tests in collaboration with IDRA Group’s FSA partners.

5S is a closed loop regenerative injection with aux servo pump for efficient recharge, that gives you total control of pressure and velocity, with high dynamic force necessary to fill difficult castings, and an incredibile amount of technological enhancements to give you superior results.

360° view of the new 5S injection system

STRONG

At all speeds (even 10 m/s) the rod side of the injection cylinder remains always pressurized, allowing a perfect control with no cavitation of the hydraulic fluid.

- Maximum dynamic force of the injection cylinder always available (2nd phase).

- Improved dynamic force.

- Better quality of the cast part.

SIMPLE

Only one valve for injection speed control, which is inserted in the inlet side of the injection cylinder.

- Better control.

- Less stress and heating effect.

- Less stressed manifolds, tubes and seals.

SUSTAINABLE

5S is designed to maximize energy saving and to achieve a long lasting life, in order to improve the eco sustainability of the machine.

- Hydraulic fluid consumption reduction up to 54%.

- Low energy consumption.

- Efficient recharge and programmable pressure.

- Long lasting components.

SMOOTH

An hydraulic cushion is mounted with special design that manages the flow of the hydraulic fluid coming out of the rod side with constant counter pressure.

- Fluid never discharged to the tank.

- Hydraulic fluid not emulsified.

- Completely smooth first step.

- Reduced mechanical noise during injection.

STABLE

5S innovative High Dynamic Force system brings revolutionary stability for injection parameters. This patented regenerative injection is giving first-class repeatability for first and second stage of velocity, while the intensification piston controlled by closed loop gives amazing final pressure.

- Unrivaled stability.

- Top-notch repeatability.

- Excellent final pressure.

NEO debuts the new Guarding system developed by Idra Group following the ‘Foreco. Forever’ philosophy: eco-sustainability and efficiency. The innovative system comes with reduced manufacturing costs and impact: the toggle guarding can now be eliminated using a closed system with light barrier protection, and difficult to manufacture sheet metal gear guards are no longer needed.

The NGS goes the ‘less is more’ route with a simplified electrical installation, a minimalistic design that reduces components and removes cable and switches. These improvements - together with a DC motor with direct belt drive - allows for a faster movement of the guards and a quicker cycle. The new design is also easily customizable: customer name and logo can be added to rear panels and colour scheme can easily be modified on request.

KeyPoints

- Servo drive

- Faster Guard movement

- Reduced Wear

- Simplified Design

- Total machine protection

- Easy customization

NEO comes equipped with the new over-theedge Drive Control Pump System developed by Idra Group. The DCP has a new architecture, that can accomplish the same efficiency with smaller kW motors, thanks to a new MasterSlave, closing unit, an improved PLC control and a new Injection Accumulator charging unit, that charges independently from the closing and core puller system.

IDRA Cell Controller is a brand new 4.0 architecture developed by IDRA and available in all the new machines, to perform efficiently the software requirements for complicated cells. From a single ‘Cell Controller’ unit, you can now control the DCM and all the peripherals of the automation cell with an easy to read, easy to customize user interface.

IDRA Cell Controller brings a new level of connectivity and integration, with a seamless flow of data IDRA Cell Controller exchange between DCM and the peripherals, to give you full control over production and process traceability. In a single screen you have a complete diagnostic analysis of the cell, greatly improving set-up and maintenance times and costs.

The DCM software is standard to give 100% reliability, and the Cell Controller offers complete flexibility and customization for many different configurations.

DISCOVER IDRA'S ARCHITECTURE 4.0

- Lower maintenance controller costs for peripherals

- High quality data and comprehensive integration

- Total safety control

- Easy customization and integration process

- Improved OEE efficiency

- Industry 4.0 ready

DOWNLOAD

VIDEOGALLERY

00:00 Intro / Welcome

00:29 Difference between a three platen toggle machine and two platen toggle free machine

6:21 Outro

00:00 Intro / Welcome

00:23 Shipping a Giga Press

1:23 Outro

00:00 Intro / Welcome

00:25 The 5S injection, which stands for Strong, Simple, Stable, Smooth and Sustainable.

7:08 Outro